HOW TO FIX THE IRON AND ADJUST THE HEAT REGULATOR

The rapid development of ironing models, from those that only provide heat, to the addition of various features, requires the user to always up-grade the science of learning these new features. Not only on the iron, all electronic items will always change, both features and models.

Fortunately, although all electronic goods undergo changes, but do not forget the basic function of the electronic device.

In this article I will not discuss the working principle of ironing, because I am sure readers already know it.

I will discuss some of the frequent damage to these electronics, including;Thermo fuse's broken.

Ironing products are now equipped with thermo fuse.

Unfortunately, in some brands, thermo fuse can not be removed (permanently installed).

To handle it, just connect the thermo fuse legs by means of a jumper using a 1.5 mm electric wire cable.

When wrapped around the wire at the foot of the thermofuse, try to tie the wire coil perfectly, because if the wire connection is wobbly, the incoming current is unstable, it is feared that it will damage the heating element.

And the wire does not touch other parts such as the base plate, or ironing cap plate, because it can drain electricity to the wearer.

The cable broke.

The use of an iron driven back and forth makes the cable position prone to break. Although it has been wrapped in thick knitted yarn,-which is the protection of the cable from high current and maintains the elasticity of the cable when used,-still the disconnection of the cable is inevitable, especially at the base, the part that most often moves around. The solution is to replace the cable with a good quality.

Its features are thicker cable diameter as a sign of more copper fibers.

Thermostat does not work.

Thermostat is the part of temperature setting that we can adjust as desired. The way this thermostat works is when the temperature has reached its climax according to the settings, it will automatically cut off.

This cut off is due to the bimetallic slab expanding, thus releasing its contact into the heating element.

When the heat has subsided, the plate will "straighten his body" and make contact again.

Common damage to thermostats include:

- Dirty contact,this is visible on the blackened contact area. This can be solved by sanding.

- Derat screw potensio temperature control themostat wear. To adjust the temperature, the iron knob needs to be rotated to press the bimetallic plate.

Rotation can occur because in shafts and shaft holes are made thread / derate, so that it can easily push ceramic needles to press the bimetallic plate.

This thread is sometimes worn, so there is no emphasis on ceramic needles to push bimetallic plates, as a result the iron can not cut off (light up continuously).

To repair this damage, must replace the thermostat a set, but some brands (models), spare parts are not available on the market, so it must be sought after sense.

The way I use is to tuck a thin aluminum slab in the derat area, you can find on a softdrink canned drink.

This slab can keep the ceramic needle from pressing, but the lack of knob position must be static can not be rotated, because this plate will wear out quickly.

If you have any idea what plate is durable, please enter your idea in the comments box.

-The ironing element is broken.

Actually the damage of the broken element on the ironing product is now very rare, but does not cover the possibility of experiencing a break on the filament wire.

In the electrical store there are many spare parts elements with various models, but not all brands are available.

If you want to buy it, you have to bring an example, to be adapted to the existing model.

But there is one brand of iron whose elements are closed / patented, so it can not be removed.

For this brand, there is no other option but to replace with a new iron.

Just info, to get spare parts elements of this type, I get it from the junkman, because customers / users feel heavy if they have to buy new, while irons are damaged if sold to the most expensive junkman can only goceng.

Thermostat settings are not standard.

The standard iron is when the knob is turned left, will turn off the current, characterized by the presence of a smooth click sound and the indicator light is off.

It functions only as an on/off switch.

But sometimes an iron does not cut off even though the knob has been turned left, with the indicator light indication still on.

For this problem, the thermostat must be re-tuned, the following ways;

- Turn the heat regulator potensio to the left until it knocks.

- Use a screwdriver (+), place it on the bolt inside the heat regulator potensio, turn the screwdriver to the right while holding the heat regulator potensio so as not to follow the screwdriver rotation.

- When you have heard a click, it means that the thermostat has been cut off.

- Remove the screwdriver, swirling potensio left right, supposedly when the round runs out to the left, there will be a click of the cut off sign.

- You can adjust where the cut off position, by reducing the rotation to the left, after the sound of cut on, turn the screwdriver again to the right until it is heard click cut off.

-The first step of improvement

Every time an ironing patient comes, they complain they must not be hot iron, I have never encountered a complaint like a dead iron.

Whereas the name of the dead iron must not be hot, while the iron is not hot, can mean the heat is not maximal, or just warm.

Of course we can not argue customers with the topic "iron difference is not hot and dead", can-can customers even ilfil and blurred,hehehe.

We should just agree with the customer, although we still hold the principle, between not hot and dead is clearly different.

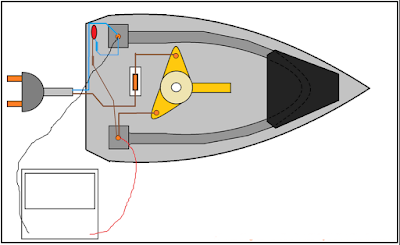

The first step of iron repair is "not hot" using a multi tester.

Attach both red and black multi tester probes to the iron plug, then rotate the heat regulator potensio knob, see the movement of the tester needle.

Indications of the movement of the tester needle are;

- If it's silent, there's a broken iron inside.

- if the move is unstable,it can be suspected the contact area thermostat is dirty.

- if the needle moves to the right and does not go down even though the knob is turned out to the left, then the iron is fine, the problem may be in the customer's outlet that is not correct.

You can directly check at your power outlet, surely tu iron directly on.

However, you have to offer the customer to reset themostat in order to cut off when the heat control knob is turned out to the left.

Not to mean "let it look work", but this is a professional action, so that the customer's iron is set standards, not only safe for customers, but also satisfaction, because we pay attention to its safety.

Posting Komentar untuk "HOW TO FIX THE IRON AND ADJUST THE HEAT REGULATOR"